History and perspectives: Development from a “hidden champion” to high-flyer

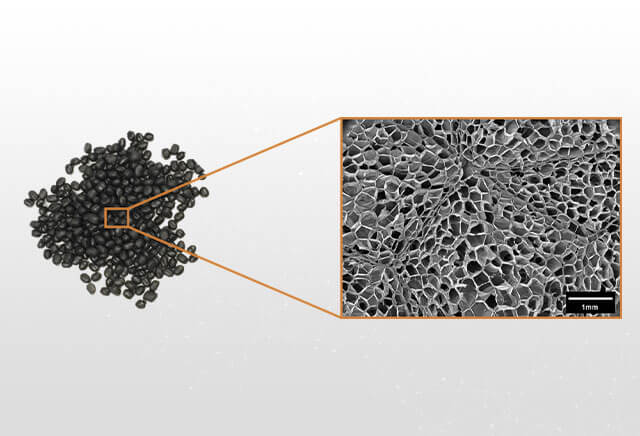

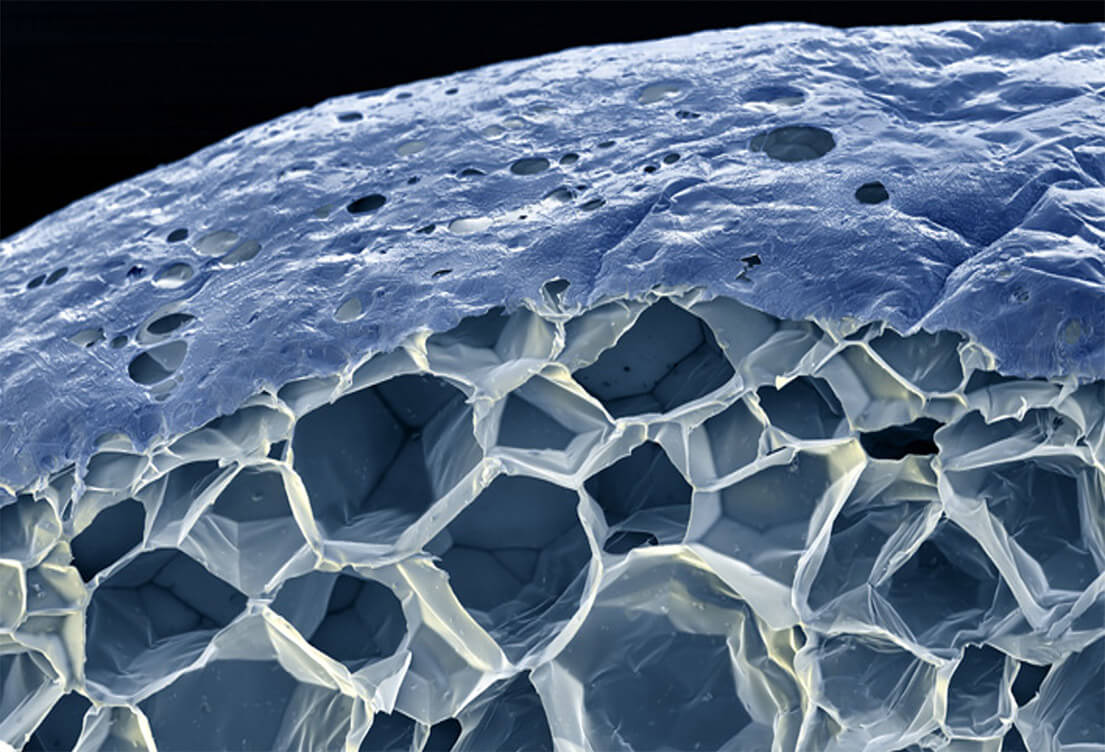

At the very beginning there was the experiment. In the 1980s, an extensive series of tests with particle foams resulted in an innovative material that seems to be able to master modern challenges effortlessly: Expanded polypropylene (EPP). Ultralight and environmentally friendly, robust and recyclable, creatively formable and toxin-free – the list of positive material properties of EPP is as long as it is impressive. It is precisely this impressive profile of properties that makes expanded polypropylene a real all-rounder of the future, which has also helped the sustainable particle foam to enjoy frenzied development. An impressive triumphal procession that is far from over.

A material steeped in history

The story of EPP is a family story – that of the particle foam family. What is often lumped together in everyday language as “polystyrene” is actually a whole range of versatile particle foams that are revolutionising the industrial and design sectors alike with their specific material properties and the resulting, amazingly versatile fields of application.

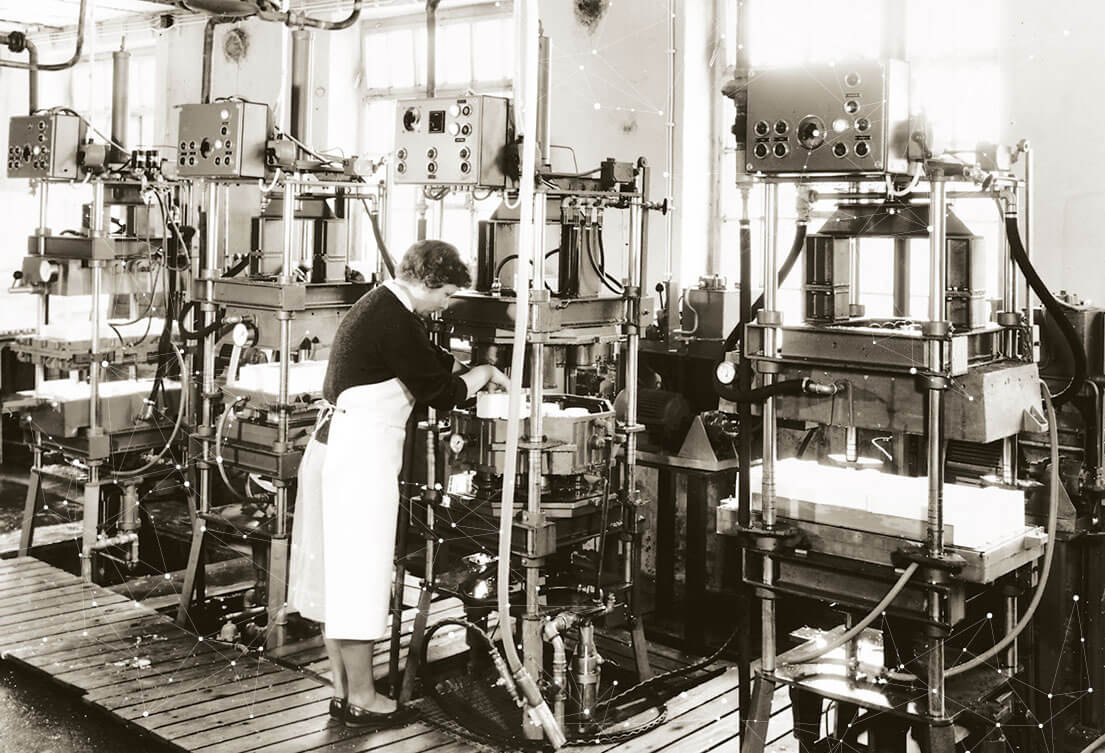

“Like a genie in a bottle, a firm white foam emerged from a shoe polish can in 1949.” BASF reminds us of the invention of the 100-year-old material polystyrene in an extremely visual way. With the invention of expanded polystyrene (EPS), the inventor Fritz Stastny heralded in the birth of particle foams in the middle of the 20th century. He and his scientific team succeeded in impregnating polystyrene (PS) granules with a hydrocarbon as an expanding agent and welding them together with heat to form a foam.

The “process for the production of porous masses of polymers” – the production of expandable polystyrene – is patented. Today, global demand for expanded polystyrene already exceeds eight million metric tons annually, with the construction industry in particular valuing EPS for its excellent insulating properties.

A new particle foam is also being developed in both Europe and Japan at the same time: expanded polyethylene (EPE). Primarily due to its good shock-absorbing properties, viscoelastic deformation behaviour and great flexibility over a wide temperature range, EPE is used above all for the protection of shock-sensitive goods as well as in the fitness sector.

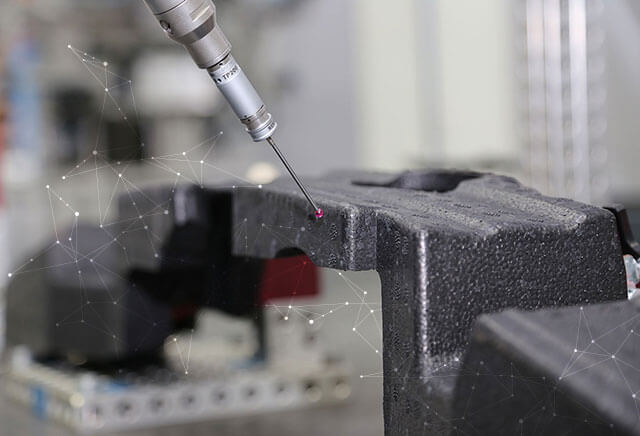

In the mid-80s, the particle foam EPP is introduced. EPP is characterised in particular by its high structural strength, high energy absorption rate and good resilience combined with an extremely low weight. Furthermore, EPP scores additional points with its suitability for use with food, its recyclability and the extensive design possibilities for the creative industry.

Today: Inspiration for industry and design

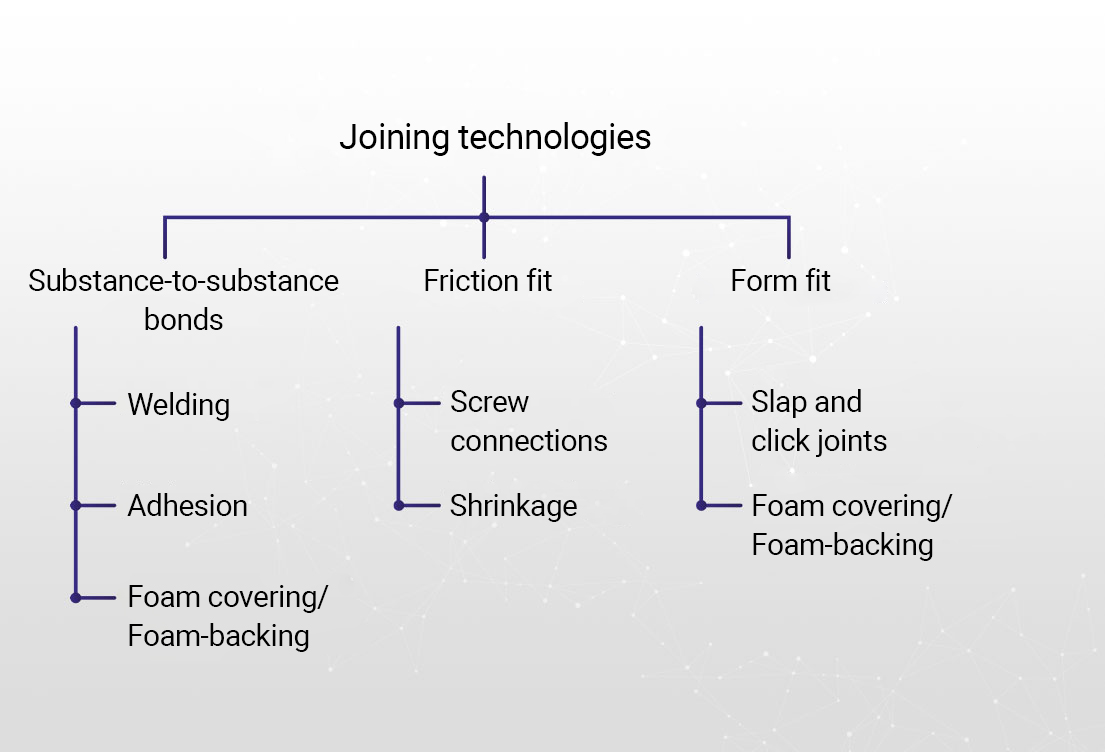

The main field of application for expanded polypropylene continues to be decisively shaped by the automotive industry. Above all, the material’s suitability for lightweight construction, its good retraction behaviour under static and dynamic loads, its functional reliability over wide temperature ranges, and its resistance to chemicals and oil made expanded polypropylene the favourite among foam materials. EPP is also the preferred material in the field of electromobility, as its excellent insulating properties make vehicles more energy-efficient, which in turn extends their range.

The packaging sector was also quickly conquered by EPP: As a featherweight material with impressive capabilities in terms of energy absorption, insulation and food safety, the innovative foam soon became indispensable.

After many years in which the focus was primarily on the physical properties of EPP, the creatively formable material is now also causing a sensation in the design sector – from furniture to model aeroplanes, toys to sports equipment.

A material with a vision of the future

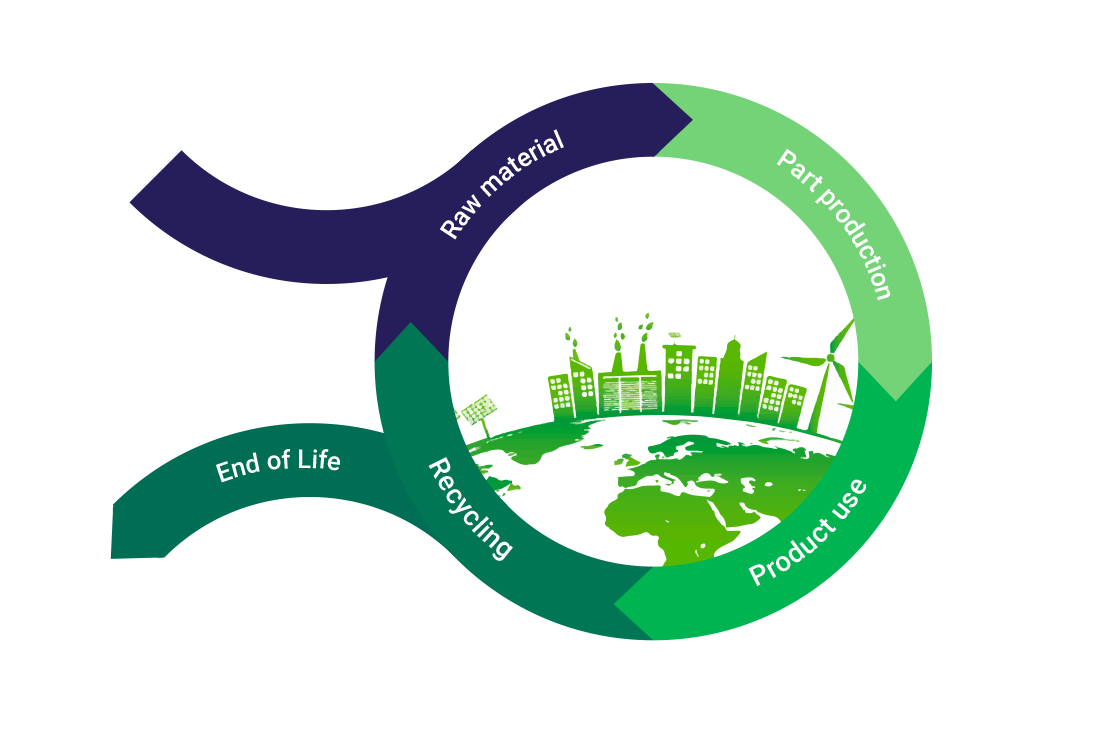

Above all, its environmental compatibility and recyclability make EPP a forward-looking material that sets new standards in terms of versatility and sustainability. This makes it all the more important to get expanded polypropylene out of the circle of hidden champions and to generate new application possibilities and sales channels.

The task of the EPP Forum, as an interdisciplinary and cross-company association of representatives from science as well as the entire value chain, is to give the innovative particle foam beads the best possible platform with regards to research and development, production, processing and application. One of our current focal points: Together with plastics experts and industry professionals, we are promoting EPP as an ideal lightweight and insulating building material for the leisure and camping sector.