Use of EPP in the areas of insulation and ventilation

EPP is a master material when it comes to heating. The excellent insulating properties over a wide temperature range and the thermal dimensional stability are what make expanded polypropylene the ideal material for insulating enclosures. When it comes to protecting sensitive cables, EPP is ideal. Functional elements embedded in the foam enable pressure-resistant and pressure-tight cable runs with bend protection and strain relief. Sensor receptacles, hose couplings and active venting or drainage also become incredibly easy. In addition, foam condensate drip trays made of surface-coated EPP meet all the important requirements for preventing heat pumps or ventilation units from icing up. Condensate drip trays made of EPP are not only very light and attractively priced, they are also waterproof, insulating, dirt-repellent and robust. Due to these and other properties, expanded polypropylene is also used in the field of ventilation technology. In addition, EPP is fully recyclable and can be reintroduced into the raw materials cycle.

Insulation

From insulating packaging for hot or cold drinks to wall cladding for the caravan – with its insulating properties, expanded polypropylene ensures the temperature is right. Due to its precision-fit production, particle foams made from expanded polypropylene are now indispensable when it comes to manufacturing insulating enclosures and casings. EPP is an environmentally friendly way to save energy and costs.

Insulating enclosures for water tanks in solar systems

EPP plastic is used, among other things, in the construction of insulating enclosures for water storage tanks in solar systems. These hold up to 500 litres of water, which must not cool down, even in winter. Therefore, the storage tanks are efficiently and accurately encased with an insulating enclosure made of EPP.

The result: Efficient thermal insulation. This is reflected in the water temperature, which is kept constant by the EPP enclosure. This great insulating performance has been confirmed by the Fraunhofer Institute for Solar Energy Systems: Compared to PU flexible foam, EPP insulation gives off 25% less heat with the same thickness. The optimised shape of the EPP moulded part further increases this saving.

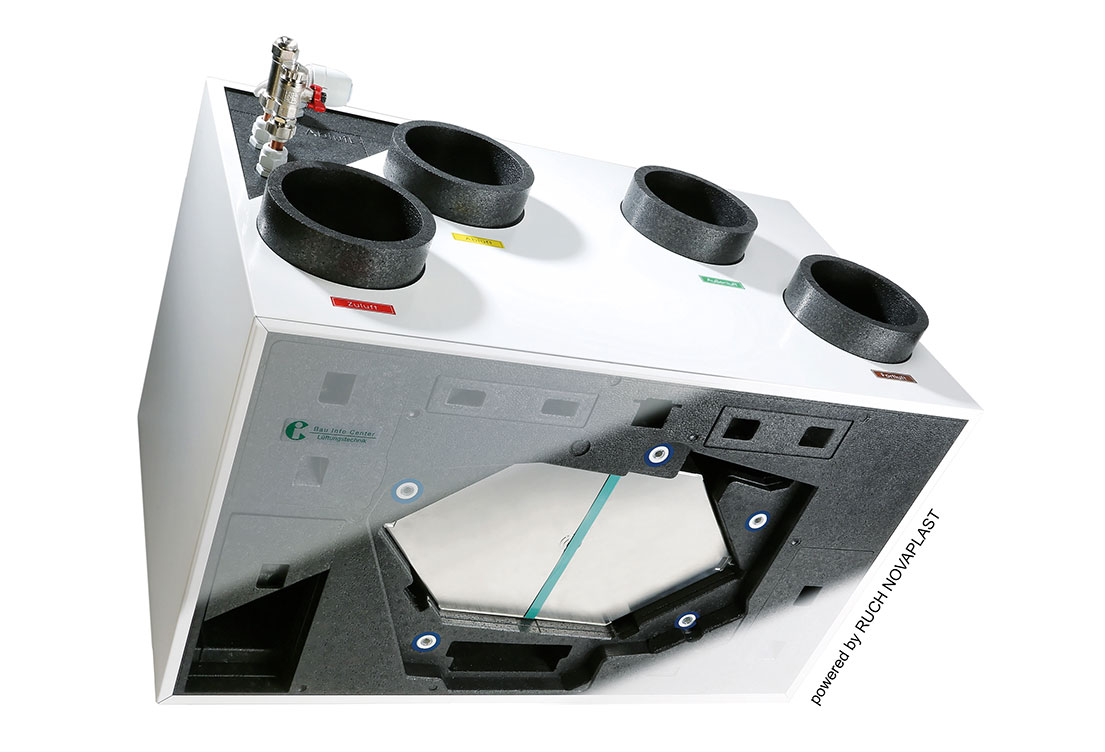

Air conditioning and ventilation technology

The resilient EPP foam is moving into more and more homes in the form of state-of-the-art ventilation technology. Extremely stable yet elastic, moulded parts made of EPP can be used to hold valuable component parts such as control boards, fans and filters and effectively protect them from external mechanical influences. And because the individual parts are not screwed onto the enclosure but inserted directly into precisely fitting indentations in the EPP foam, material and costs can be saved. Due to the excellent thermal insulation properties of expanded polypropylene, less energy is lost within the systems. This increases the effectiveness of the ventilation system, saves resources and protects the environment. The tool technologies available today for structuring the surfaces of EPP parts also enable a high-quality visual design that blends in perfectly with the living space.