Joining techniques – bonding EPP with other components

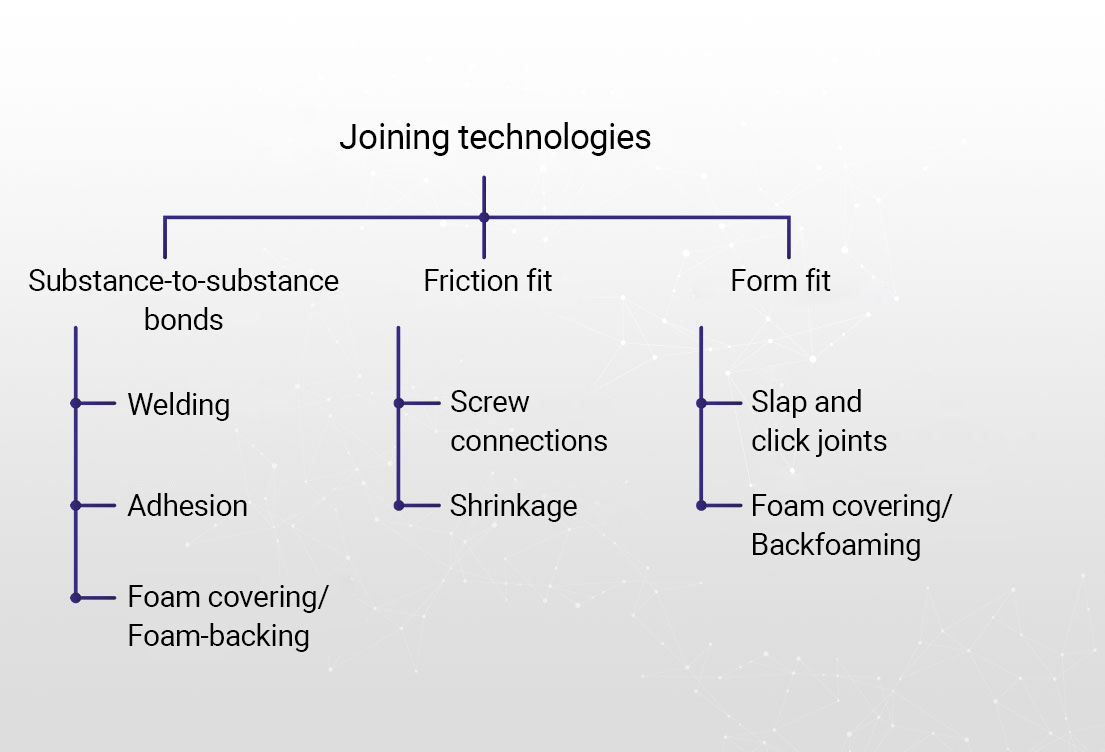

To use the material EPP in a wide range of applications, joining or bonding techniques are required. As dissimilar materials are often joined together, it is necessary to highlight possible joining technologies during the development phase of the component. In the following, the possibilities of joining or bonding EPP moulded parts to each other as well as to other materials are presented.

Substance-to-substance bonds

Substance-to-substance bonds are characterised by the fact that the individual components are connected using atomic or molecular forces. This type of bond can be achieved with the friction welding process, the adhesive process, or by foam-covering or backfoaming.

The friction welding process

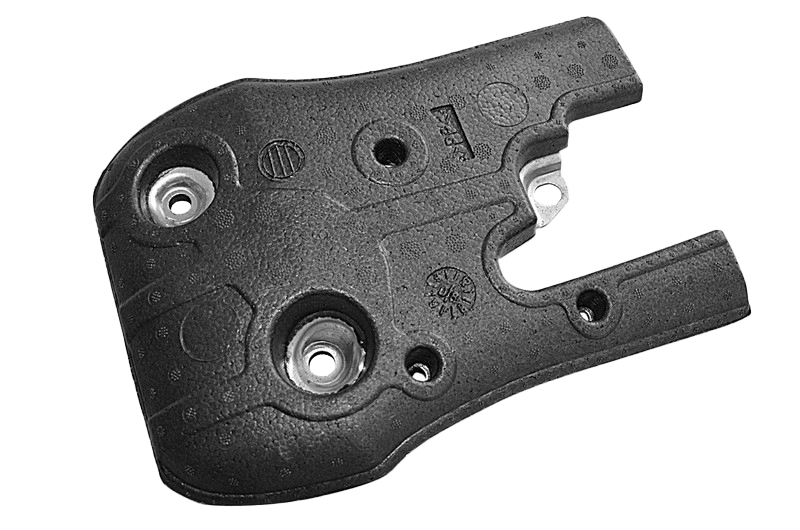

Friction welding is one way of joining EPP material to a joining member. The friction welding process uses pressure, friction and the resulting heat to join two materials together with high-quality, long-lasting results.

Our member EJOT has succeeded in bringing an extremely stable fastening element for EPP foams onto the market. During the friction welding process, the fastener is inserted directly into the EPP particle foam. The innovative element then bonds with the molten material.

The adhesive process

The adhesive process is the term used to describe a bonding technique in which the parts to be joined are bonded together with the aid of an adhesive. The bonding mechanism of the adhesive joint is created by cohesive and adhesive forces, which characterise the grade and quality of an adhesive joint. Olefin-based plastics, such as EPP, are difficult to bond together due to their hydrophobic and non-polar surface properties. However, specially developed adhesive solutions enable durable and high-quality EPP bonding. Suitable pretreatment of the surfaces to be glued, for example by roughening, thermal flame treatment or corona pretreatment, leads to an increase in the adhesion effect and therefore to better bonding quality.

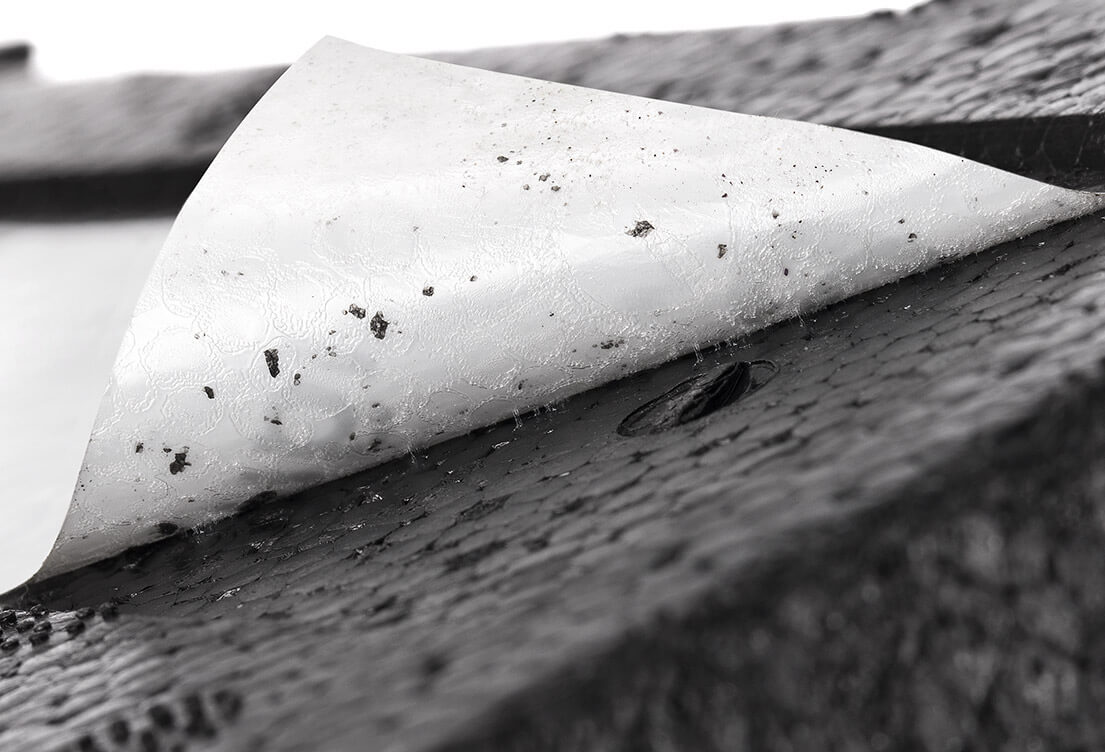

Foam-covering / backfoaming

Backfoaming and foam-covering using EPP and compatible thermoplastics also makes it possible to achieve positive substance-to-substance joints. The fusion of the components within the joining zone results in a bond caused by interdiffusion of the polymer chains. With this technology, the already formed and trimmed patterns or foils are inserted directly into the mould cavity of the moulding machine, and then backed with foam during the moulding process. Connecting elements can also be embedded in the foam, such as the “K-Fix elements”. When inserted into the production mould, the fasteners are embedded in the foam during the manufacture of particle foam components, forming an inseparable bond with the component. Further components can be connected using these foam-covered elements. Due to the substance-to-substance bond, these fasteners can withstand high loads and vibrations.

Friction fit

Foamed components as alternative lightweight solutions, mostly made of EPP, are currently becoming increasingly more significant. The friction fit is the most favorable way of joining two parts and is one of the most common types of connection for EPP parts. The connection of the parts to be joined is ensured by the forces at work (pressure, tensile or frictional force).

Screw connections

EPP foam components can be screwed together if the geometric design of the plastic fixture and screw is suitable. Due to the low density of EPP, a thread-forming screw connection can be carried out without pre-drilling. Our member EJOT has developed a screw that can be screwed directly into the foam without a pilot hole. With the help of an optional snap-in hook, additional components can also be attached later on.

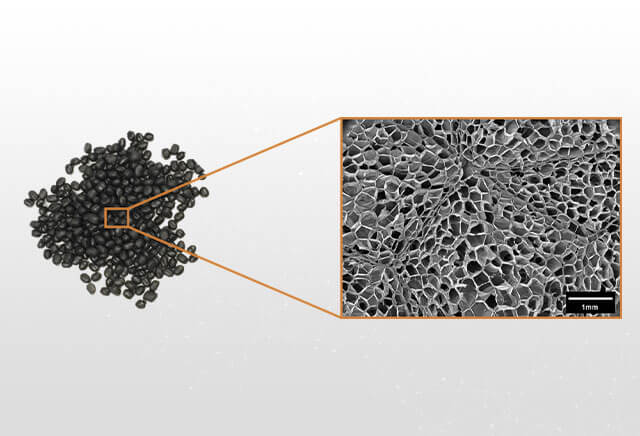

Shrinkage

Due to the shrinkage of EPP (between 2 and 3% for commercial EPP grades) that is dependent on density, a friction fit results when inserts are covered in foam due to the different thermal expansion coefficients. Shrinkage is a major contributor to the connection, especially for components with many gaps or ribbed foamed-in-place elements. For example, components that need to be covered in foam are often designed with ribs or undercuts to achieve a friction fit.

Form fit

If at least two connecting parts interlock, this is referred to as a form fit. Due to the compressive forces at work, the connecting parts prevent each other from coming loose from one another. This joining method can be realised, among other things, using snap or click connections.

Snap and click connections

Due to its high resilience, EPP is ideally suited for connection using snap and click joints. Snap connections are form fit connections with a wide range of design options. During assembly, a protruding point, for example a hook or a bead, is temporarily moved and thus engages in a recess (undercut) in the connecting part. Particularly in the area of heating and air-conditioning technology, moulded parts made of expanded polypropylene create energy-efficient solutions. Thanks to the special design with plug-in or click connections, devices remain easily accessible for maintenance and repair.

Foam-covering / backfoaming

In addition to the material advantages of EPP, further benefits can be generated by foam-covering or backfoaming additional components. Structural elements such as metal or injection-moulded inserts can be embedded into the foam to strengthen the material locally. This multi-part concept demonstrates the enormous functional abilities of particle foam. Inserts adapted to the load can be integrated into the foam components for mounting purposes.