EPP as a raw material – light and stable

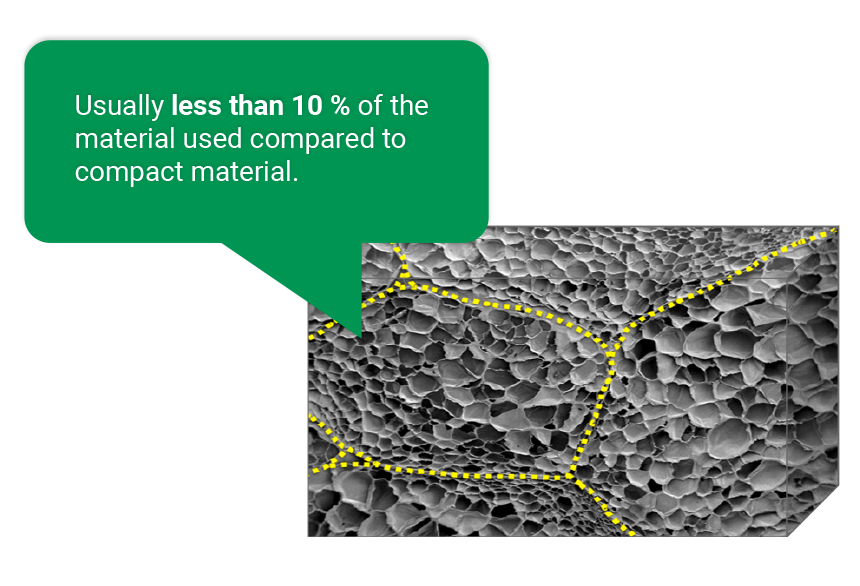

In addition to the cost effective production of EPP, the use of foams in a wide range of industries also helps to conserve resources. As a rule of thumb, less than 10 per cent of the material, which is required in the production of compact material, is needed to produce expanded polypropylene foam. And that’s not all: As a raw material, EPP also stands out thanks to other positive properties.

Light weight

One of the most prominent properties of EPP is its incredibly low weight. And that is no coincidence: EPP consists of approx. 75 to 98 percent air. The particle foam made from polypropylene has very low densities of 20 to 250 kg/m³. The low material content makes the innovative foam extremely resource-efficient compared to compact plastic.

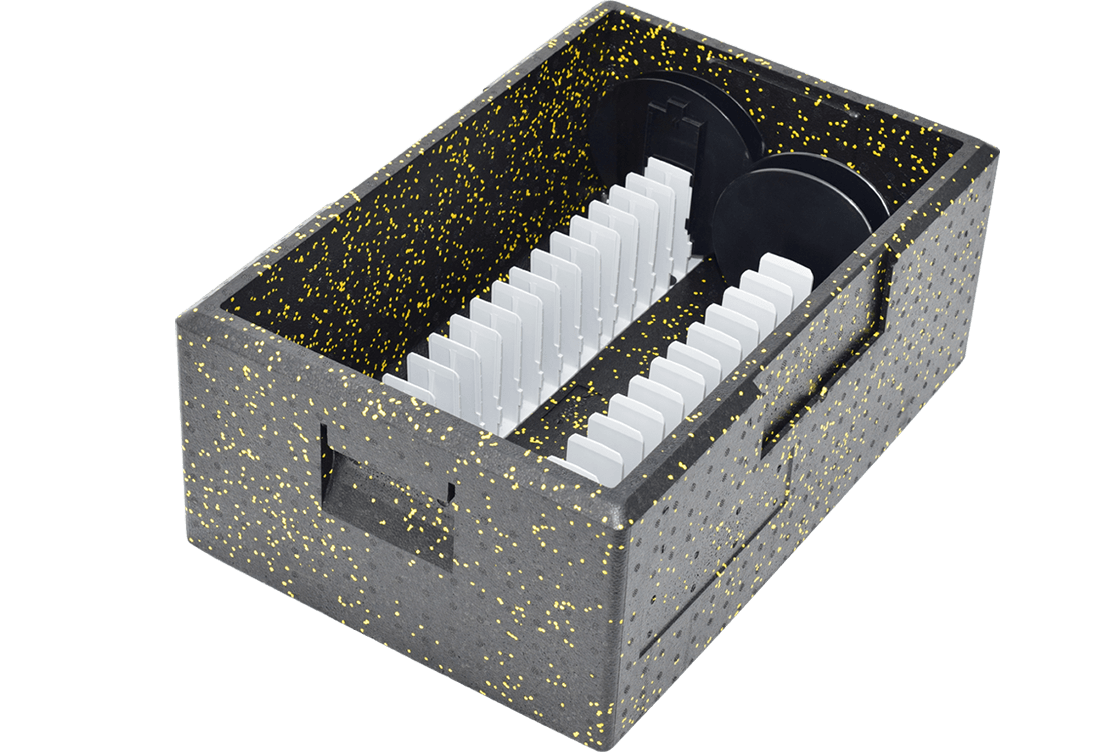

Stability

EPP is extremely robust. Thanks to its durability, expanded polypropylene is ideally suited for the production of reusable transport packaging – especially for industry and trade. This reduces the amount of disposable packaging and materials.

Free from harmful substances

The innovative particle foam is 100 per cent pollutant-free and not hazardous to water. EPP can therefore be used in a wide variety of areas, such as the manufacture of toys or in the food industry. Sliding vehicles made of EPP, like the one in this picture, are absolutely safe and harmless for children, they withstand various stresses and strains and can be used both indoors and outdoors.

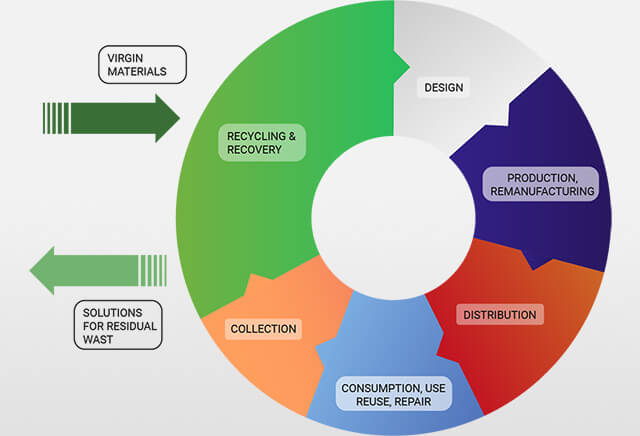

Recyclability

Expanded polypropylene does not contain hydrocarbons, volatile organic components or other components that are considered harmful to the environment. For this reason, EPP can be recycled easily and returned to the material cycle. Defective products or foam waste can be ground down and immediately fed back into the production stream.