The recycling process for EPP – diverse and sustainable

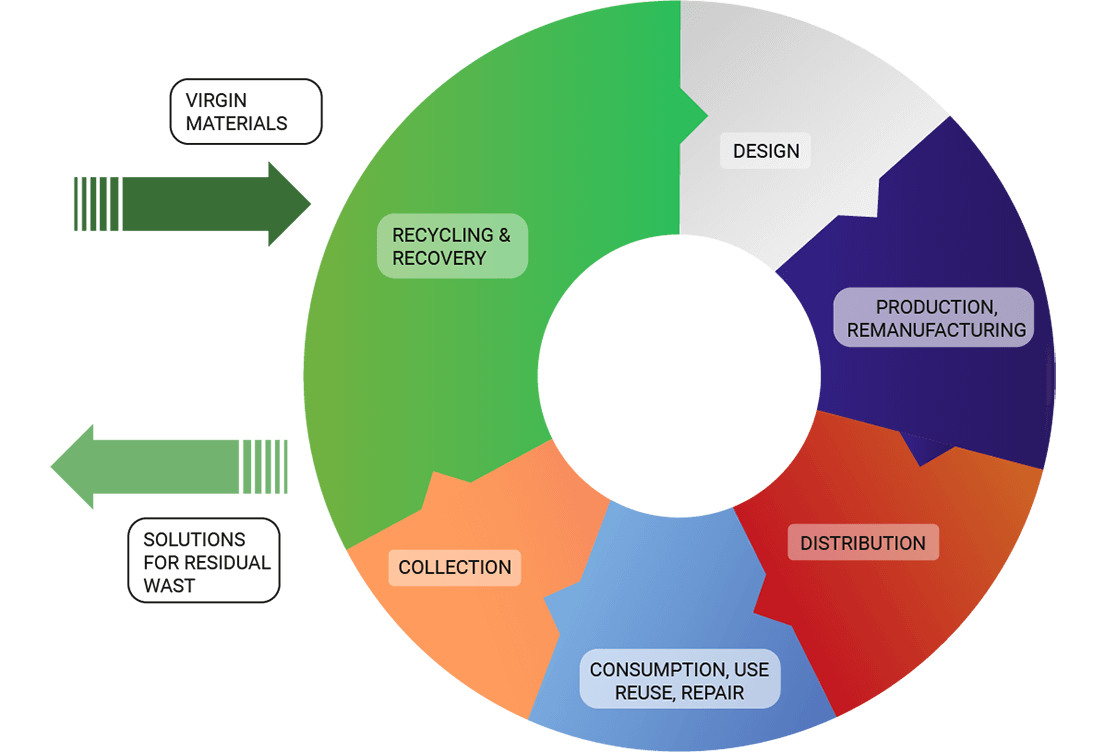

In addition to numerous positive properties and a wide range of applications, the recyclability rounds off EPP’s profile as “material of the future”. Transport packaging made of EPP can be used again and again and remain in circulation for several years. Moulded parts and components made of expanded polypropylene are extremely resistant and have a long shelf life. Expanded polypropylene can be combined with polypropylene in many ways to create recyclable mono-material solutions. This simplifies the recycling process because the materials do not have to be separated from each other.

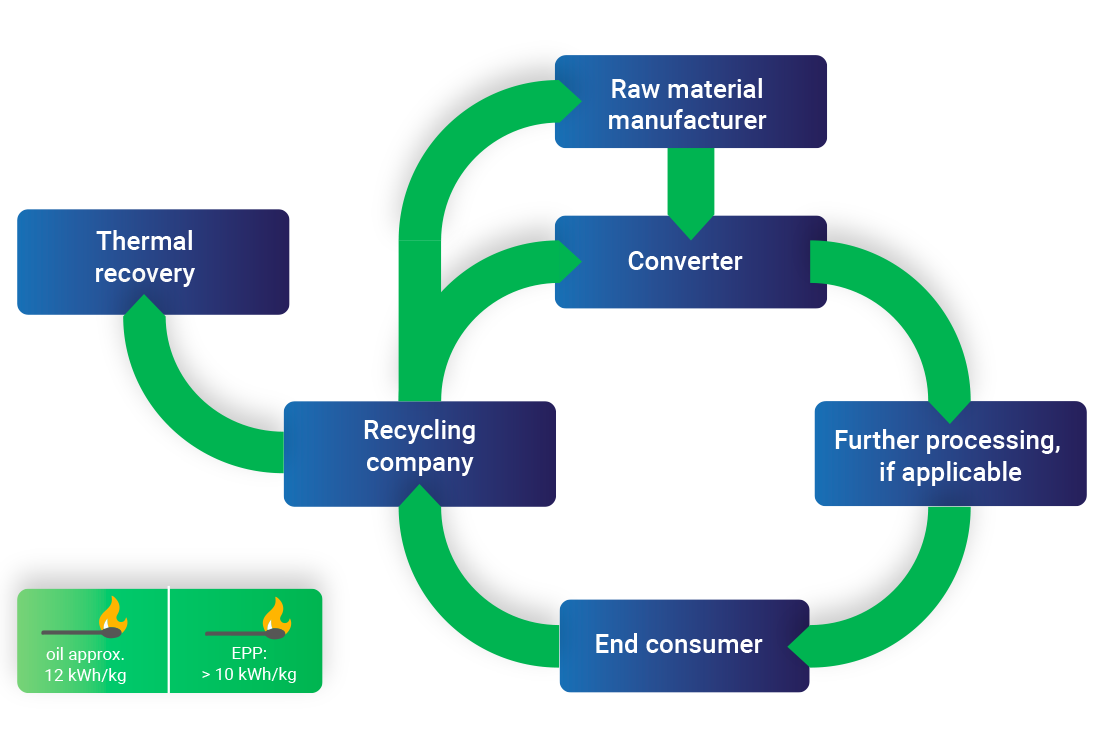

Should an EPP part no longer be required, at the end of its life it can be…

- compacted,

- shredded,

- freed from dust and sieved

- and processed into polypropylene regranulate.

Regardless of the industry – from bumper components and sun visors to high-performance mechanical sandwich components made of monomaterials – EPP products can always be recycled and returned to the material cycle.

Polypropylene regranulate

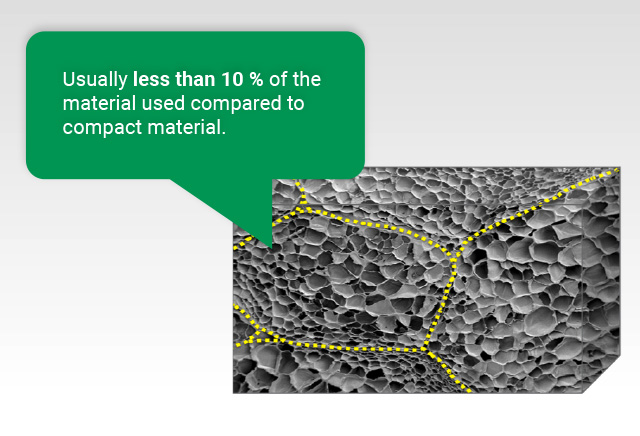

Expanded polypropylene can be moved into the polypropylene recycling stream and is therefore fully recyclable. The market for PP regranulate and ground stock has already been established. The goal in terms of the circular economy is to repeatedly return EPP to the PP cycle. At the end of its service life, the material EPP can be used as regranulate with injection moulding and extrusion products. This reuse enables the effective conservation of resources.

The use of recycled EPP for the production of new EPP beads is the subject of current developments. EPP parts that cannot be reprocessed should be sent for thermal energy recovery. The material can also be used further in this area: Thermal recovery through incineration is easily possible with very good energy yields. The heating value of EPP is comparable to that of petroleum (EPP: >10 kW h/kg, oil: approx. 12 kW h/kg). If EPP components that cannot be re-processed are thermally recycled, the energy content can still be recovered and used. And landfilling is not required under any circumstances.